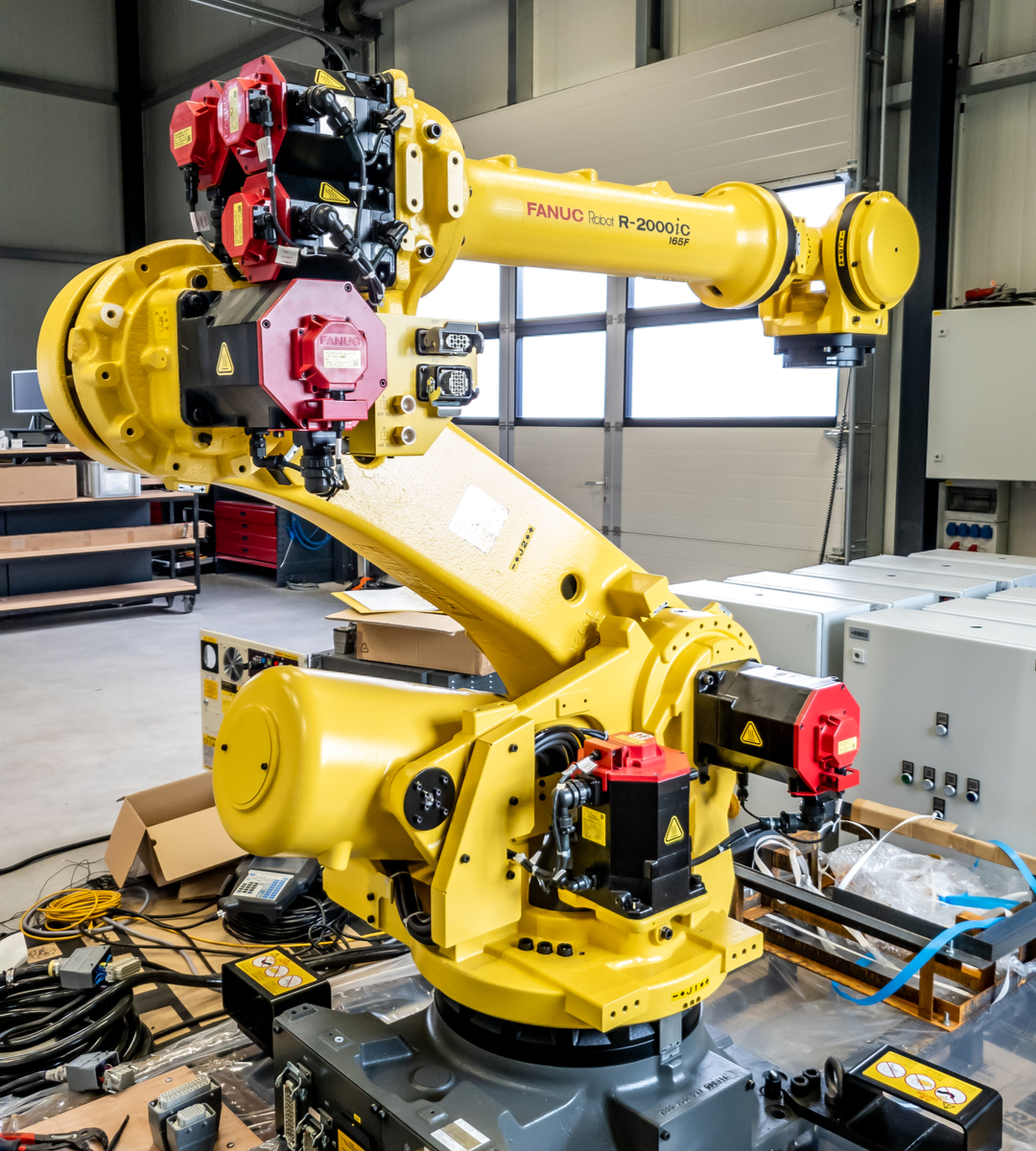

In today’s rapidly evolving manufacturing landscape, industrial robots and robotic manufacturing have emerged as key drivers of innovation and efficiency. The incorporation of robotics into manufacturing has transformed the industry. It offers a variety of benefits to businesses seeking to improve productivity, quality, or competitiveness. As the demand for automated solutions grows manufacturing robots play an increasing role in determining the future of manufacturing.

Industrial robots are also known as manufacturing robots. They are specialized machines that carry out a variety of functions in the manufacturing environment. They can be used for welding, painting,, packing and picking and much more. Industrial robotics, the field of study and applications of these robots concentrates on improving the efficiency and accuracy of manufacturing operations.

Automated Solutions Australia is one of the companies on the forefront. They are specialized in industrial robots that offer flexible automation to manufacturing clients. ASA’s industrial robots help clients to gain a competitive advantage in the market by increasing productivity and quality. ASA industrial robotics are highly sought after by companies in a wide range of sectors, such as pharmaceuticals, electronics and automotive.

The advantages of using industrial robots in manufacturing are numerous. One of the main benefits is increased efficiency and productivity. Industrial robots are capable of performing repetitive tasks with accuracy and consistency, leading to greater output rates and lower time to complete. This does not just increase overall productivity but also allows businesses to meet ever-growing consumer demands with ease.

Industrial robots are also a part of greater quality control during manufacturing processes. Robots are able to complete tasks more accurately and with higher security. This leads to better quality products. As a result, you will have a higher rate of satisfaction from customers and a better reputation for the company.

Industrial robots aren’t only reliable and durable, they also save money. While the initial investment in manufacturing robots may seem substantial, the long-term cost savings are substantial. By streamlining production processes and reducing the demand for manual labor, companies can lower operational costs and achieve a quick ROI. Additionally, industrial robots can be operational 24/7, optimizing the utilization of resources, and decreasing the costs per unit of production.

Another compelling advantage of industrial robots can be their impact on workplace surroundings. They have been developed to reduce noise levels. This creates more relaxing and quiet working environment. Additionally, their speed and precision help to make the workplace safer, by minimizing the risk of injuries and accidents.

The integration of industrial robots plays an important role in creating jobs and the future jobs. Although there could be some concerns about automation displacing human workers However, the reality is industrial robots create new opportunities for job opportunities. These include jobs in robot programming, maintenance and supervision as well as roles which support robot-driven manufacturing.

In the various industries, businesses continue to reap the benefits of industrial robots, and the manufacturing sector continues to embrace the technology, it is changing the industry. Industrial robotics with its ability to improve effectiveness, efficiency, and quality is reshaping how products are manufactured.

In conclusion, manufacturing robots are a paradigm shift in manufacturing. The fusion of these technologies is enabling businesses achieve unprecedented levels of performance and precision, as well as competitiveness and efficiency. With the need for automated solutions continues to grow, industrial robots are poised to play a pivotal role in determining the future of manufacturing, driving innovations and propelling companies to be successful on the global stage.