Wire rope lubricators and wire cleaners and other advanced tools are vital in the complicated field of maintenance for cables. The quality and durability of the cables is essential. These cutting-edge devices are essential in ensuring that cables work well and last longer in many industries. Rope lubricators and wire cleaners are important for cable maintenance. In this post, we examine their roles, benefits and the transformative impact on the overall efficiency. For more information, click Cable Cleaner

Understanding the lubrication of wire rope

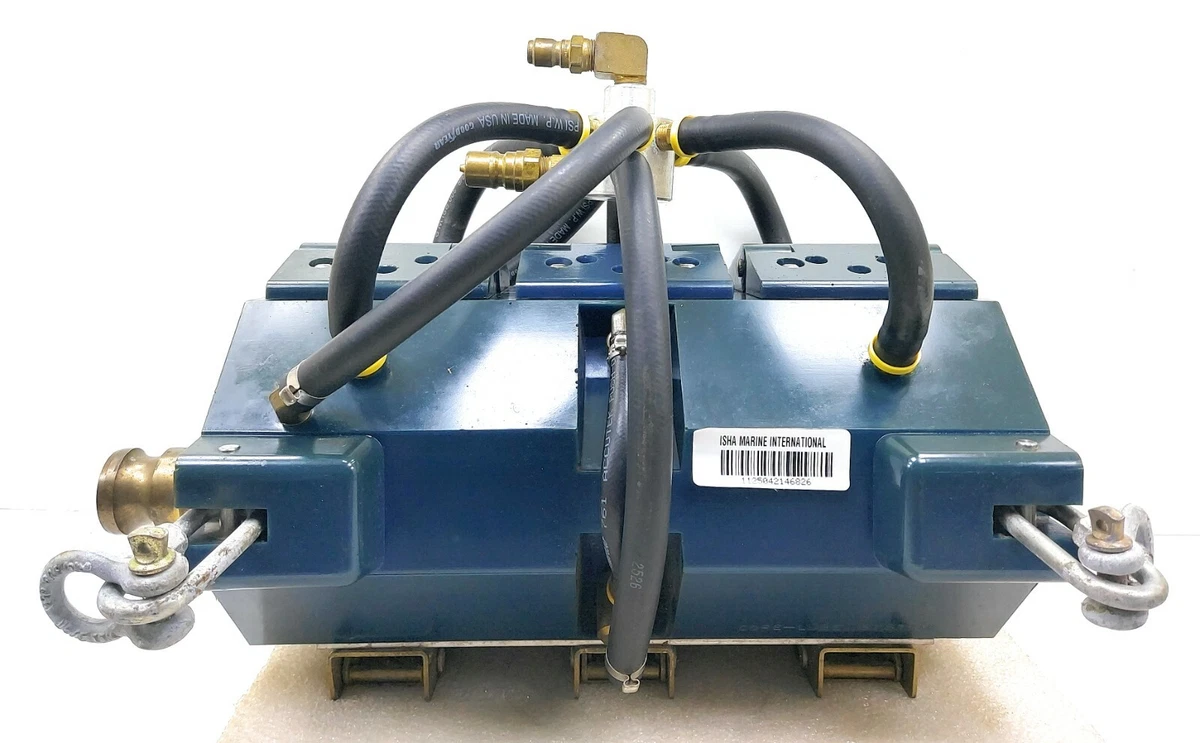

Wire rope lubricators are also known as wire rope lubricators are special devices that apply grease to the ropes in a planned manner. This is an essential step to stop friction and corrosion as well as extending the life of the cable. The lubricator guarantees that the lubricating substance is evenly distributed over the length of the wire rope, providing the most complete protection from wear and tear.

What is the role of wire cleaners in cable maintenance?

Wire cleaners, often referred to as cable cleaners, can be instrumental in keeping the cleanliness of cables. They are designed to remove debris, contaminants, and fluids that may accumulate on the cable during various processes. In harsh environments using wire cleaning products is vital to ensure optimal performance.

Optimizing Cable Lifespan:

The usage of lubricators for wire ropes as well as wire cleaners can significantly contribute to extending the lifespan of cables. Utilizing wire rope cleaners to clean up contaminants and applying lubrication, cables are protected from harmful effects such as corrosion, friction, or external elements. The protection of the cable’s integrity translates into increased operational efficiency and lower maintenance costs over time.

Effectiveness in the application

Wire Rope Lubricators have been designed to be user-friendly and effective in application. They can be utilized on a variety of sizes and kinds of wire ropes. This allows for flexibility in the maintenance of cables. The automated and systematic application of lubrication guarantees consistency that eliminates the danger of uneven coverage that manual methods may pose.

Flexibility to Adapt to Challenges

In industries where cables are exposed to extreme environments, such as those employed in drilling, construction, or maritime operations the ability to adapt wire rope lubricators as well as wire cleaners is crucial. They are specifically designed to stand up to harsh environments and are therefore reliable tools to ensure the maintenance of cables in various settings.

Cost-Effective Maintenance Solutions for

A proactive approach to maintenance of your cables, involving the use of wire rope cleaners and lubricators is a much more affordable choice in the long-term. These advanced tools can be a minimal investment when compared to the costs of repairs, replacements or downtime that result from neglecting maintenance.

Conclusion:

Lubricators for wire ropes along with wire cleaners, are guardians of the integrity of cables. They assure high-quality, long-lasting and efficient performance across a variety of industries. The consistent application of lubrication, as well as the removal of dirt contributes to the protection of cables, thereby decreasing maintenance costs and increasing the efficiency of operation. Cables are still in use in critical industries, and using tools for maintenance of cables that will help keep them in good working order and successful is vital.